was founded in the year 2008 in Coimbatore, manufacturing V Tork Knife Gate Valves Dealer in Delhi India Uni-directional/Bi-directional with innovative product features to serve the diversified species of Industries like Mining, Power, Water & Waste water and Pulp & Paper.

V-TORK® CONTROLS was founded in the year 2008 in Coimbatore, an Engineering hub of South India for manufacturing Knife Gate valves with innovative product features to serve the diversified species of Industries like Mining, Power, Water & Waste water and Pulp & Paper. The mission is always towards excellence and innovation to serve the valuable customers. We have a well-managed and organized team of employees, working together for the same motive to provide quality products to the clients. The experienced staffs of experts pay utmost attention to attain the perfection and high level of customer satisfaction. The company quality management system is certified to ISO 9001-2015.

V-TORK General Knife Gate Valves are specially designed and manufactured according to MSS SP/Customized to meet the worst working conditions in Pulp & Paper, Mining & Steel, Power & Chemical Industries, Water Treatment Industries to handle Semi-Solids, Abrasive Slurries, Dry-Ash, Chips, Fiber contents Pulps etc. The compact design of the valves facilitates light weight, minimum space for installing, easy operation and maintenance. The compact Knife Edged gate is manufactured from Stainless Steel Plates of various grades irrespective of Body material.

The bottom of the Gate is having Knife type edge which can cut through Semi-Solid or Paste type Pulp with possible fiber and solid contents, Fly ash, Chemicals with solid contents and ensure smooth shutdown operation and tight shut-off. The Knife gate valves are available in wide range of material. Trim options are available to suit individual requirements for various working.

A typical Unidirectional Knife Gate is one of the few application-specific designs among the industrial valves which features a single-piece rugged and compact cast body design that offers optimum performance and serves from general to complex demanding applications for material flow purposes. An economical, easy to operate shut-off valve that regulates the flow in the piping system of high viscous fluids. Its design ensures minimum contact between moving parts and is achieved by having the gate, which is practically held between a few layers of gland packing, not touching the body parts during most of its travel. The gate and seat final sealing is achieved with non-sliding motion aided by gate wedges located in the body. This feature enables the valve to handle abrasive particles in the media better than other designs. The beveled bottom edge of the gate from which the name KNIFE is derived enables positive closure of the valve, even when solid particles tend to settle at the bottom of the body. As an effective solution for the leakage problem in Media containing particles, Knife gate valves are used in various sectors of industries.

• Uni Directional, Wafer Type

• Size 2” to 120” (50mm to 3000mm)

• Metal Seated / Resilient Seated

• Single Piece Construction

• 150 PSI CWP

• Standard: MSS SP-81, MSS SP-148, MSS SP-151

• Uni Directional, Lug Type

• Size 2” to 120” (50mm to 3000mm)

• Metal Seated / Resilient Seated

• Single Piece Construction

• 150 PSI CWP

• Standard: MSS SP-81, MSS SP-148, MSS SP-151

• Uni Directional, Flanged Type

• Size 2” to 120” (50mm to 3000mm)

• Metal Seated / Resilient Seated

• Single Piece Construction

• 150 PSI CWP

• Standard: MSS SP-81, MSS SP-148, MSS SP-151

• UniDirectional, Wafer Type

• Size 2” to 120” (50mm to 3400mm)

• Bonneted / Bonnet Less

• Metal Seated / Soft Seated

• 150 PSI CWP

• Standard: AWWA C520-10

• UniDirectional, Lug Type

• Size 2” to 120” (50mm to 3400mm)

• Bonneted / Bonnet Less

• Metal Seated / Soft Seated

• 150 PSI CWP

• Standard: AWWA C520-10

• UniDirectional, Flanged Type

• Size 2” to 120” (50mm to 3400mm)

• Bonneted / Bonnet Less

• Metal Seated / Soft Seated

• 150 PSI CWP

• Standard: AWWA C520-10

• Uni Directional, Flanged Type

• Size 18” to 40” (450mm to 1000mm)

• Metal Seated, High Temperature Finish

• Single Piece Construction

• Standard: NFPA 85

• Uni Directional, Square/Rectangular Port Type

• Size 150X150 to 2500X2500mm

• Metal Seated

• Fabricated Construction

• Standard: V-TORK Std

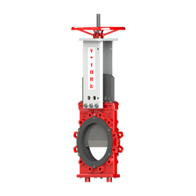

The V-TORK® B SERIES Bi directional Knife Gate Valve is designed to handle pressure or flow from either directions, mainly for ON-OFF applications in abrasive and corrosive slurry lines of various industries.

• Bi Directional, Lug Type

• Size 2” to 40” (50mm to 1000mm)

• Resilient Seated (U Seal)

• Single Piece Construction

• 150 PSI CWP

• Standard: MSS SP-81

• Bi Directional, Lug Type

• Size 2” to 54” (50mm to 1350mm)

• Dual Elastomer Seals with Retainer Rings

• Single Piece Construction

• 150 PSI/300 PSI (18” to 54”) CWP

• Standard: V-TORK Std

• Bi Directional, Flanged Type

• Size 2” to 64” (50mm to 1600mm)

• Dual Elastomer Seals

• Single Piece Construction

• 2” to 30” 150 PSI CWP/ Above 30” 100 PSI

• Standard: V-TORK Std

• Size Range: 2” to 40” (50MM to 1000MM)

• Pressure Rating: 2”- 40” - 150 PSI CWP

• Flow Direction can be mounted in both flow directions

V-TORK slurry Knife Gate valves are designed for heavy duty purposes to isolate flow, even in the most demanding process conditions. The complete valve is built around an ease of maintenance concept which contains Purge port, Replaceable Retainer ring, Dual Elastomer Seals for long operational period.

These Soft Seated Knife Gate Valve features a unique design that provides bubble-tight shutoff in either direction. The valve is designed for isolation and on/off applications in the paper, chemical, mining, power and waste water industries. It is designed to handle clean, dirt, viscous and corrosive Liquids, sludge, fibrous slurries, clean and corrosive gases.

• Bi Directional, Lug Type

• Size 4” to 24” (100mm to 600mm)

• Metal Seated / Resilient Seated

• Split Body Construction

• 150 PSI CWP

• Standard: MSS SP-81, MSS SP-148, MSS SP-151

• Bi Directional, Flanged Type

• Size 2” to 40” (50mm to 1000mm)

• Resilient Seated (U-Seal)

• Two Piece Fabricated Construction

• 150 PSI CWP

• Standard: MSS SP-81, MSS SP-148, MSS SP-151

• Bi Directional, Lug Type

• Size 2” to 54” (50mm to 1350mm)

• Dual Elastomer Seals with Retainer Rings

• Single Piece Construction

• 150 PSI/300 PSI (18” to 54”) CWP

• Standard: V-TORK Std

• Bi Directional, Flanged Type

• Size 2” to 64” (50mm to 1600mm)

• Dual Elastomer Seals

• Single Piece Construction

• 2” to 30” 150 PSI CWP/ Above 30” 100 PSI

• Standard: V-TORK Std

• Bi Directional, Lug Type

• Size 2” to 36” (50mm to 900mm)

• Dual Elastomer Seals with Retainer Rings

• Single Piece Construction

• 740 psi CWP/51 bar/Class #300

• Standard: V-TORK Std

V-TORK AWWA/water Knife Gate valve standard describes Bonneted / Bonnetless and one piece/two piece construction which is made of stainless steel /cast iron /ductile iron body with resilient or metal seated knife gate valves. Theses AWWA valves are especially used in water, wastewater, and sludge water systems. V-TORK Valves are specially manufactured by AWWA standard to suit critical water applications.